Case Study New Viessmann Boiler in Streetley

Being accredited by the major boiler manufacturers has many advantages, long warranties, great backup, bespoke training on existing and upcoming products.

The most useful from a homeowners perspective is if you are looking for a particular product and that needs an installation company who understands the boiler and its capabilities. The Viessmann 200-w range is the only out of the box boiler with weather compensation as standard, so for a new boiler you need to know how it works and where this setup should be best used.

After receiving a phone call from a new client who had found me through the Viessmann website and discussing their needs it became apparent that the 200 range was the best option.

This particular job was as part of a whole house renovation and extension, with the system being upgraded from a Baxi combination boiler to a Weather compensated 35kw system boiler with a 300 litre cylinder to supply the extra bathrooms that would be added during the project. The heating system itself would incorporate both radiators and underfloor heating so would need to run at different temperatures to get the perfect comfort and efficiency levels.

New Viessman 200-w range

What makes the Viessman 200-w range so unique is its ability to run at the lowest possible temperatures meaning the boiler is almost always condensing. The needs of the client were agreed and the specifications finalised.

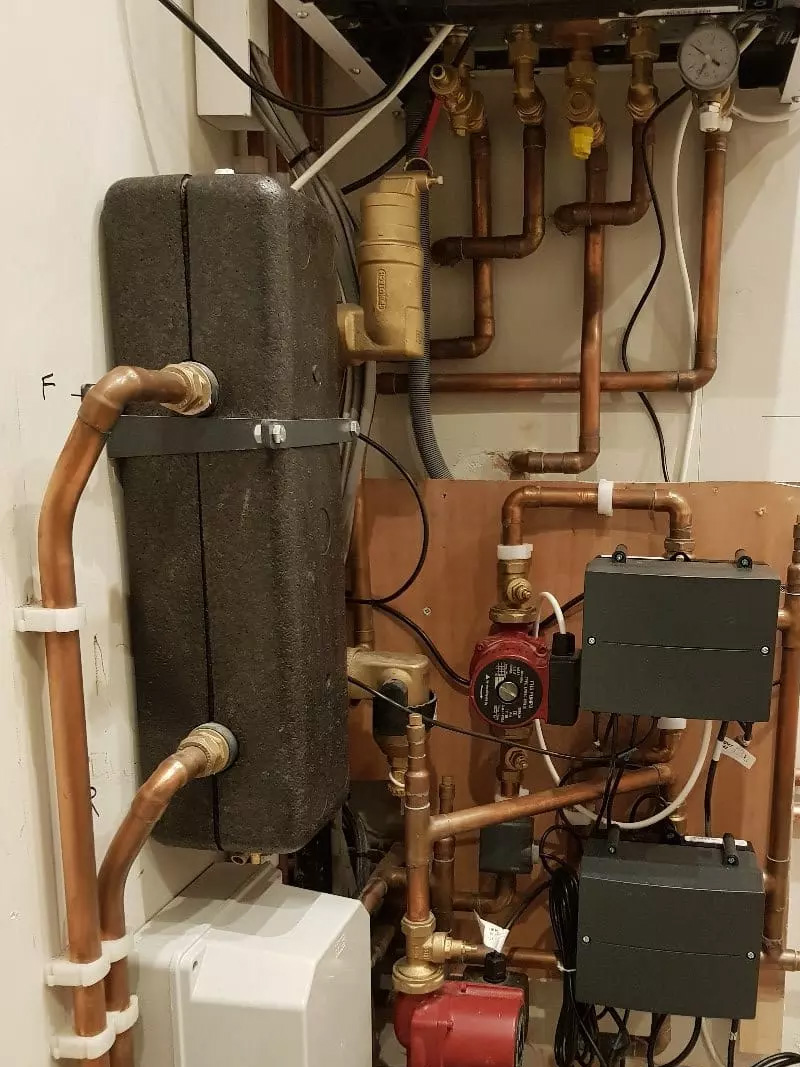

The breakdown of the main components were as follows

- Viessmann 200-w 35kw system boiler

- Viessmann vitocell 300 litre cylinder

- 4 pipe hot water priority setup

- Secondary hot water circulation

- Low loss header

- 2mixed circuits with mixer motors

- Weather compensation controls

Start of the projet: New boiler in Streetley

The start date for this project was delayed a couple of times due to various factors with planning builders, but finally towards the end of summer 2019 the 1stfix pipework was installed to allow the walls to be plastered.

One of the challenges fitting a new boiler to an existing systemis the change over from old to new without causing to much disruption to the customers heating and hot water(not so bad in the summer, but imperative in the winter).

The underfloor heating installation was carried out by a company who lay the wet screed floor due to cost and that all in one solution being a better option.

Our part in it was getting the heating pipes to the manifold and back to the mixing valve by the boiler. The temperature itself will be controlled by the boilers heat curve. Once the walls and ceiling were all plastered and painted it was time to install the new boiler and cylinder and change the hot water over to work through the cylinder.

The great thing about mains pressure cylinders is the flow rate and pressure are un excess of 25litres per minute after having a new 32mm mdpe main installed early in the project for this very reason. The 4pipe setup is a very simple way of heating the cylinder at a rapid rate without affecting the temperature of the radiators or ufh with high temperature heating water.

The reheat time from stone cold is less the 25 minutes so will really have very little effect on the house comfort. One of the unforeseen challenges with this job was that theViessmann 200-w range changed mid project which meant slightly different specifications and product codes which led to the wrong parts being ordered by myself and a few bits missing due to a new way of ordering parts that used to come with the boiler. After calling Viessmann out for the boiler notcoming on(donut moment, new boiler switch under the boiler, instructions for dummies required) they pointed out I had installed the old range of mixing valves o the new range of boiler and the two were not compatible.

These things happen and we were ableto return the wrong ones and order the new ones which arrived with 48hours.Another challenge was to fit everything in the larder unit including boiler pipe work and the mixer valves, low loss header etc. It was a bit tight but a bit of thought and we just about managed it. When installing any new boiler and turning it on for the first time I’m always nervous that it all comes on and works the way you planned.

The really great thing was the commissioning process was very easy all through the new touch screen on the boiler fascia. Once all the components are registered the software is ready to go and then you can make any adjustments to the heat curve, timings and hot water set temperatures etc. With the innovation of smart controls the fact that the Viessmann 200-w is wifi enabled out the box without any external control purchase needed. Through the vicare app the whole system can be monitored and controlled totally from your mobile device.

We many to get the system up and running before Christmas which I was very relieved about.Once everything was working just the way the customer wanted we could then register all the warranties and notify the works with gas safe register for building control to sign the build off.

Mr Sangar knew what he wanted right from the start and as a person was great to get on with and very approachable. We had many a conversation throughout to make sure everything was done to the specifications we outlined from the start and the outcome was one I am super proud of.